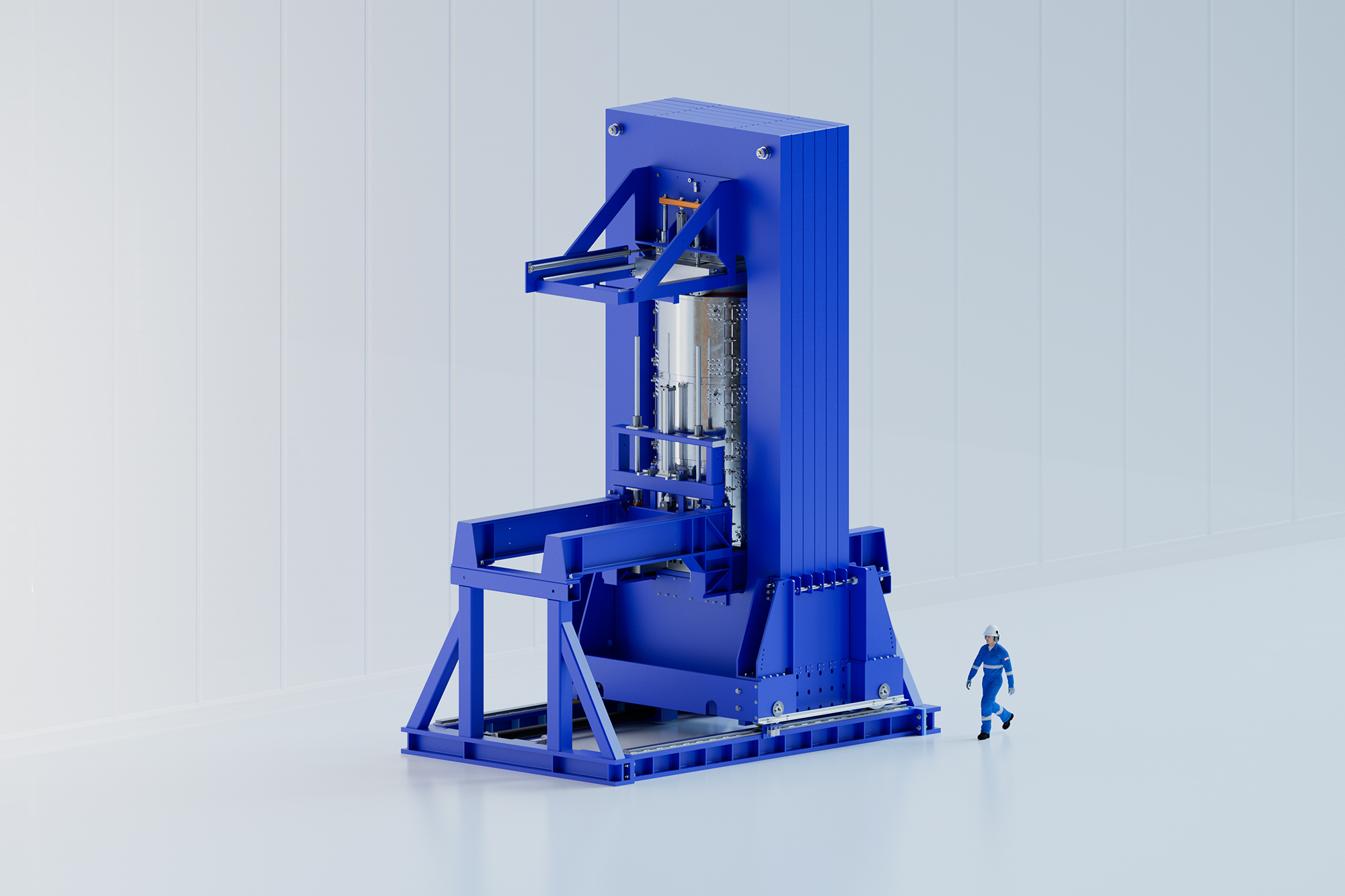

Hot Isostatic Presses

EPSI is a leading manufacturer of hot isostatic presses (HIP) with many decades of experience. We deliver HIP systems to customers producing components in a wide range of materials such as metals, ceramics, composites and plastics. Our solutions are also ideal for the densification of parts made by additive manufacturing methods. We have built an excellent reputation for HIPs that are fast, cost-effective and reliable, and with the necessary precision to manufacture net shape or near net shape products.

Our offering ranges from small laboratory HIP units with hot zone diameters starting from 76 mm (3”) to large production units with hot zone diameters up to 1500 mm (59”). The furnace length can be adapted to meet the customer’s necessities. Standard, off-the-shelf solutions are available for many applications but units can also be custom-designed to accommodate your specific dimensions and product characteristics.

Main features

HIP Types

Furnace Types

HIP Types

We can supply a variety of HIP solutions, all with multi-zone radial furnaces. The size can varie from small laboratory units, over medium-size and pilot production units to larger production units.

Their advanced controls and software make them easy to operate with computerized cycle programming and data logging. Uniform rapid cooling is available (diameters starting from 152 mm or 6”) to significantly increase cycle time efficiency. All units have a plug-in furnace design, making it very easy and safe to operate. They are fully automated with pre-programmed cycles including thermocouple verification before and during the cycle.

Furnace Types

The HIPs may be equipped with several different furnace module types. Depending on the necessities and limitations of the product cycle, one or multiple types can be implemented.

The following furnace modules can be provided:

- Molybdenium

- Graphite

- Kanthal

- Superkanthal

We design and install turnkey systems and provide worldwide service.

Contact us to discuss your next project.