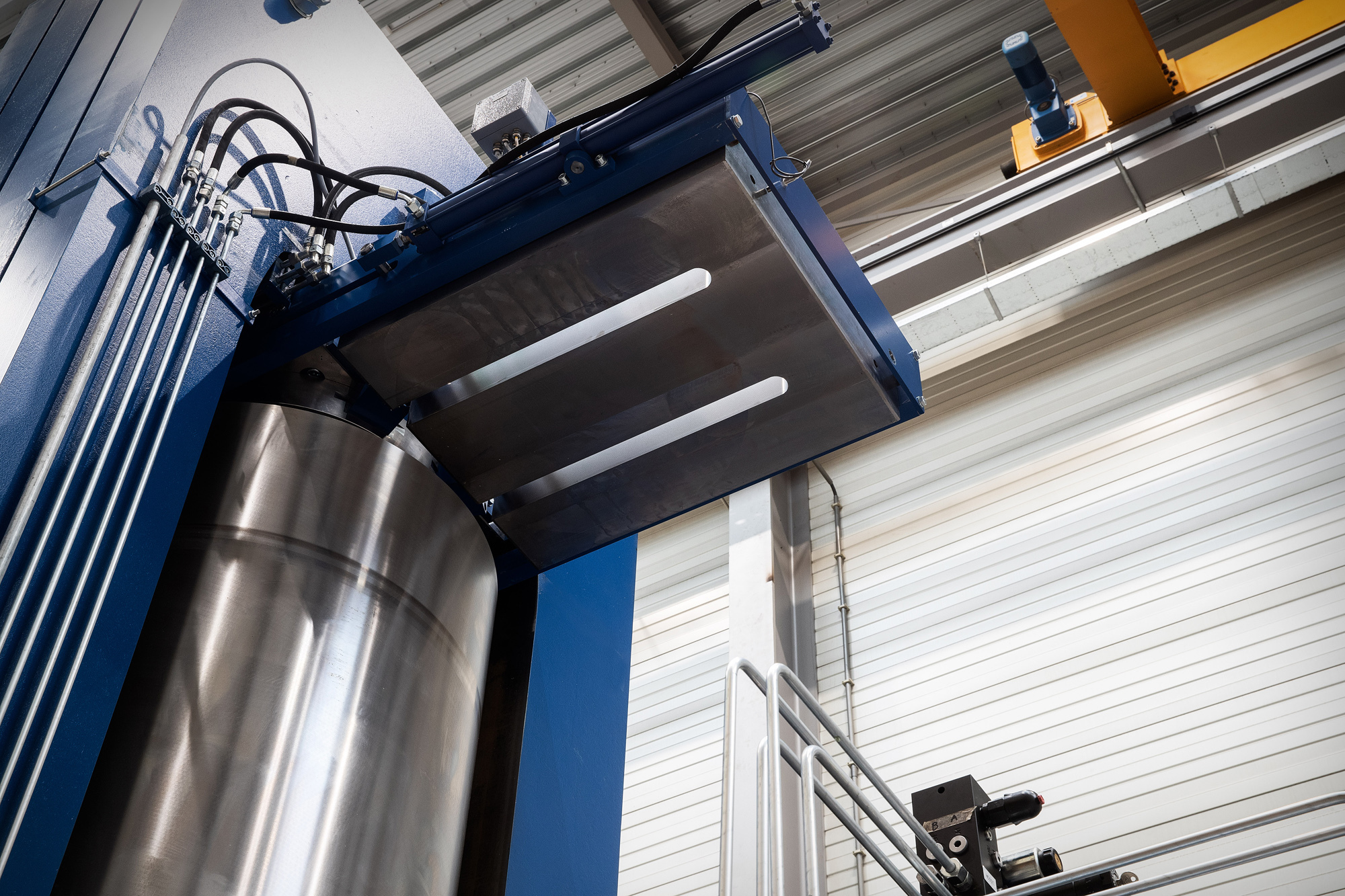

Warm Isostatic Presses

Warm Isostatic presses (WIP) combine high pressure and temperature methods (maximum 275°C / 527°F). Water or oil are used as the pressurization fluid, depending on the specifications and requirements of the application.

EPSI specializes in purpose-built WIPs which can be small, laboratory presses or larger units with a warm zone diameter up to 2 m (6 ft) or more and pressures up to 600 MPa (87,000 psi). Special vessel executions, such as an inner pre-stressed liner, filtering solutions, and diverse heating options are also possible. Warm isostatic presses can be integrated in highly automated systems which are custom designed in accordance with the customer’s production requirements. The presses are manufactured with the highest quality components and materials assuring operation of all units in the safest conditions. Cycle characteristic and monitoring are optimized using powerful software.

Main features

We design and install turnkey systems and provide worldwide service.

Contact us to discuss your next project.